Sustainability

Sustainability is integrated into processes, policies and initiatives towards the customer as the strategic focus of the company.

Environmental sustainability and safety are key factors to the success of all our products.

TIV Valves considers essential the collaboration with all stakeholders during the product life cycle phases,

including the design, assembly process and disposal operations during plant decommissioning.

Our corporate culture is simple but very well established: to work with and assist our customers

from the very early stages to after-sales service (we offer on-site maintenance worldwide) by always

providing the best combination of business support and technical expertise.

We believe in transparency and accountability, and our sustainability data reflects our efforts to become a more responsible company in a journey that began in 2020.

What is being done in terms of concrete initiatives?

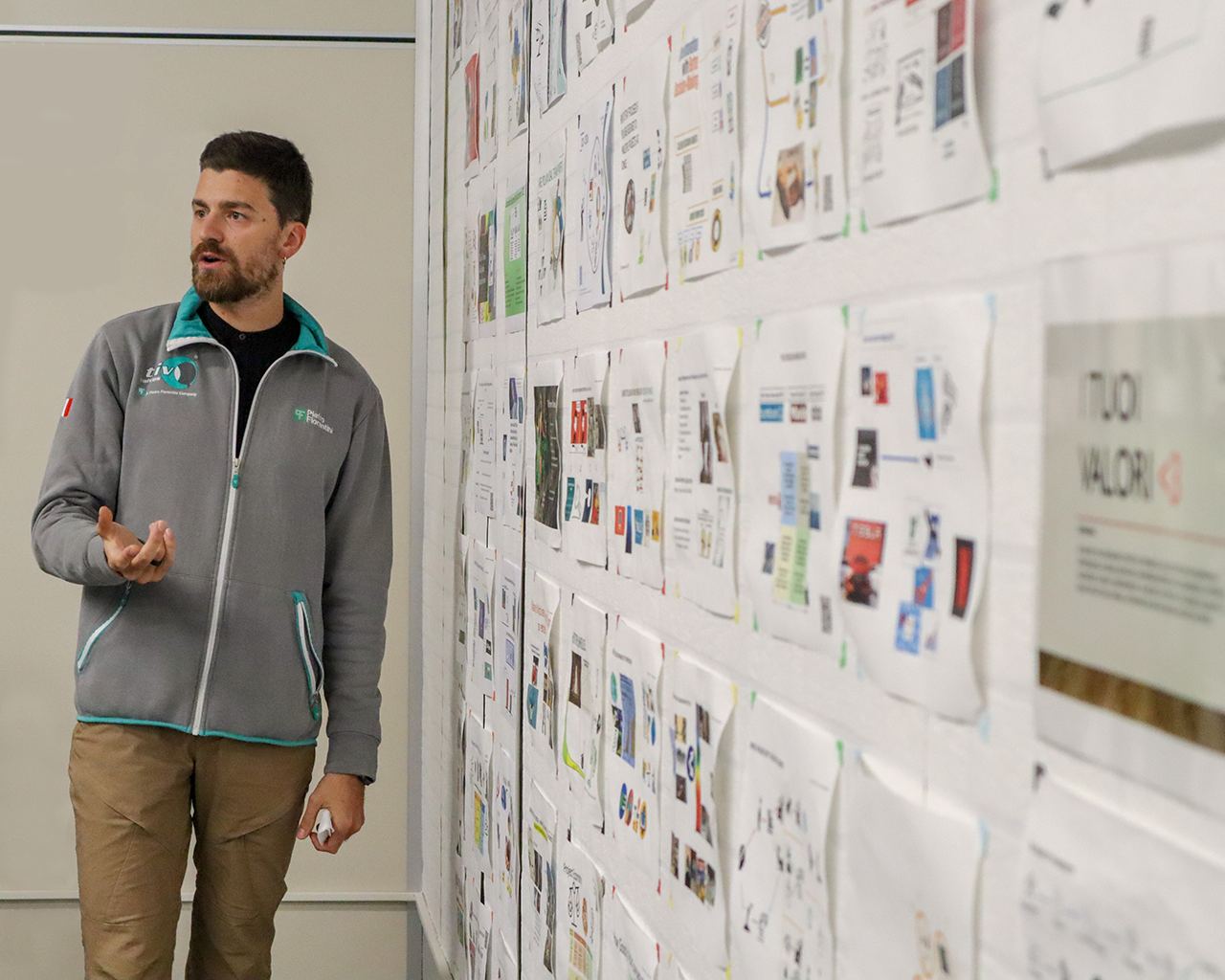

Lean and Agile methodologies

The Lean and Agile methodologies, different but complementary, coexist and integrate throughout the company because they are functional to the principles that underpin all our activities: customer satisfaction to avoidance of what does not bring value, optimisation of processes and constant comparison aimed at achieving the highest level of quality.

The Lean Manufacturing model, which originated in Japan in the mid-20th century and has been applied by Fiorentini Group for more than twenty years, focuses only on what generates value for the customer, identifying and eliminating all activities considered wasteful.

Since its acquisition by Pietro Fiorentini Group, Lean Thinking has contributed to the sustainable enhancement not only of production processes, but also of decision-making and management processes, involving all departments, offices and departments.

A dedicated office to implement the philosophy of continuous improvement (the Kaizen Promotion Office, from Kai - change, and Zen - good, better) has helped create a common culture throughout the company.

In order to cope with an ever-changing, increasingly complex world that requires great adaptability, the company began to combine the efficiency of Lean Management with Agile methodology.

Within an ever-growing network of teams and projects, professionals from inside and outside the company combine their cross-functional skills in iterative cycles.

The main aim is to provide functional releases of the project on a regular basis, to be shared with stakeholders (internal or external to the company) in order to be able to easily adapt to changes and variations and thus shorten development time.