Referenze

High Temperature

For continuous operating temperatures over 200 °C (392 °F), standard polymers and elastomers are no longer suitable. In this harsh environment static and dynamic seals are built in graphite-based materials, while the trim is metal seated.

Cryogenic

When the valve operating temperature is lower than -50 °C (-58 °F), special materials selection, design and production features are required. This know-how is the key factor to ensure tightness capability and smooth operability even with liquefied gases.

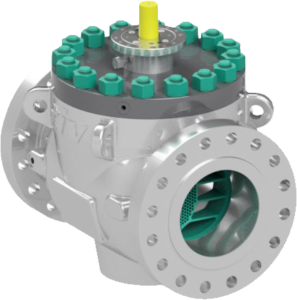

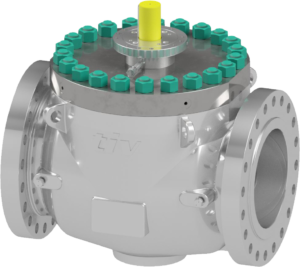

Standard

The standard deltaflux valve is designed for sweet clean gas applications and moderate minimum and maximum design temperature.

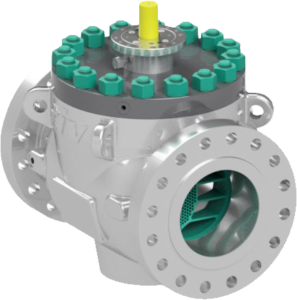

High Temperature

For continuous operating temperatures over 200 °C (392 °F), standard polymers and elastomers are no longer suitable. In this harsh environment static and dynamic seals are built in graphite-based materials, while the trim is metal seated.

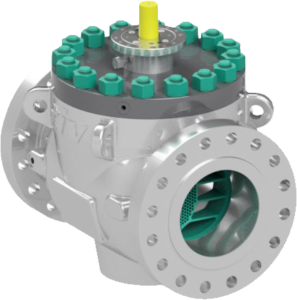

Cryogenic

When the valve operating temperature is lower than -50 °C (-58 °F), special materials selection, design and production features are required. This know-how is the key factor to ensure tightness capability and smooth operability even with liquefied gases.

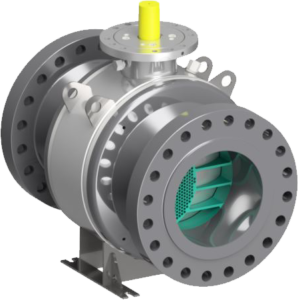

Welded body

La costruzione delle valvole Welded body prevede che l’involucro in pressione sia realizzato per saldatura, piuttostochè imbullonato. Questa costruzione, comune per applicazione di trasporto del gas permette di eliminare due importanti potenziali vie di fuga e di ridurre il costo complessivo della valvola con un’ottimizzazione dell’uso delle materie prime. La configurazione del trim è progetta […]

Bolted body

The standard deltaflux valve is designed for sweet clean gas applications and moderate minimum and maximum design temperature.

High Temperature

For continuous operating temperatures over 200 °C (392 °F), standard polymers and elastomers are no longer suitable. In this harsh environment static and dynamic seals are built in graphite-based materials, while the trim is metal seated.

Cryogenic

When the valve operating temperature is lower than -50 °C (-58 °F), special materials selection, design and production features are required. This know-how is the key factor to ensure tightness capability and smooth operability even with liquefied gases.

Standard

The standard ball valve is designed for sweet clean gas applications and moderate minimum and maximum design temperature. This valve configuration is the most competitive in term of price and lead-time.